Fiber optics is a practical instrument that is frequently utilized in the domains of engineering and applied sciences for the transfer of data across great distances. Optical fibers are translucent, bendable strands of silica, or pure glass. Fiber optic cables, which are as thin as human hair, serve as a waveguide to carry light between the two ends of the strand. Due to their reduced transmission loss and resistance to electromagnetic interference, these cables are favored over metal wires. A clear core and a transparent cladding material with a reduced index of refraction are the basic components of optical fiber. Total internal reflection keeps light inside the core. The fiber now functions as a waveguide.

The caliber of the fiber and the clarity at either end of the transmission line is crucial to the effectiveness of fiber optics. The cut ends of the wires need to be polished smooth to maximize efficiency and data transfer rate. The development of fiber polishing machine has advanced significantly during the past several years. Companies that rely on these cables now have access to a complete industry that caters to their demands. Within the fiber optic polishing sector, there are businesses that polish fiber ends on-site and others that design and provide the highly specialized polishing equipment needed for the job.

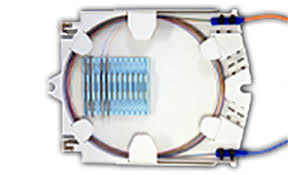

While measuring elements like apex offset, the radius of curvature, fiber protrusion, back reflection, and under-cut, optical fiber polishing machines are capable of the tight tolerances and precise repeatability needed to continuously deliver outstanding manufacturing outcomes. Yield and throughput are two crucial elements to consider when choosing optical fiber polishing equipment. Yield is a measure of consistency and quality. Productivity is gauged by throughput. The greatest of this fiber polishing fixture enables platen force, speed, and time adjustments to meet exact requirements and accurately polish fiber optic connection ends in a repeatable, dependable way.

For a variety of uses, specific polishing materials have also been created in addition to highly developed and programmed polishing equipment. These substances, sometimes known as abrasive films, are made to produce extremely exact polishing results.

Better performing fiber optic fibers are the final consequence of these very sophisticated materials and fiber polisher. They have developed into an essential workhorse for communications networks all across the world; therefore this is a significant factor to take into account.

Wuhan Sunma Technology Co,.LTD.

88, Mingyuan Road, Optic Valley, Hongshan, Wuhan 430074, Hubei, China

Tel : +86-27 8720 8018, +86-27 5177 9650

Fax: +86-27 5177 8865

E-mail: info@sunmafiber.com

Fax: +86-27 5177 8865

E-mail: info@sunmafiber.com